The Internet of Things (IoT) is real, it is here and it is providing value to business. That was the central message from Dell EMC’s Dermot O’Connell, vice president, EMEA, OEM and IoT Solutions, at the company’s IoT Lab at its Limerick campus.

O’Connell said that IoT is in use in the commercial space and providing value, insights and efficiencies in a variety of sectors, with examples from the food, agriculture and construction industry on hand.

Dell EMC is uniquely positioned, bolstered by the one-year anniversary of the great merger, to offer IoT solutions as it has a full stack offering, he said, from edge to core to cloud.

“The guys who aren’t failing at IoT are the ones who are using platforms, the ones who are going about it in a structured way”

O’Connell highlighted some of the many benefits and use cases. IoT is facilitating complete supply chain examination and tracking to highlight inefficiencies and bottlenecks, providing savings in time and cost. This is especially so in sectors such as healthcare, food and energy.

Automotive change

In the automotive industry, said O’Connell, it is changing the way cars are owned. Citing examples such as Tesla Motors, IoT has allowed vehicles to be updated over their lifetime, meaning the manufacturer can maintain a direct relationship with the vehicle throughout its lifecycle.

In areas such as heavy industry where supervisory control and data acquisition (SCADA) systems are widely used, they can be constantly updated and made safe and secure. Another example, said O’Connell, was the issue of the lone operative. Now, with IoT sensors and monitors, safety issues can be mitigated where operatives are in the field on their own, as well allowing for new supports to get their work done.

IoT technologies are also providing new revenue models and streams to be developed as a result of constant connectivity that was simply not possible previously.

O’Connell said that Dell EMC has industry’s broadest portfolio of IoT infrastructure solutions portfolio.

Marc Flanagan, director, EMEA, IoT and Embedded, Dell EMC, cited some specific instances of where these benefits are currently being seen.

He described how the WEHR Group, who make massive industrial pump and excavation equipment, had reduced downtime and unexpected failures by deploying a connected sensor network that allowed analysis of telemetry to detect the indications of failure. This allowed the company to re-organise its supply chain to have the most commonly needed parts at the right distribution centres to reduce or eliminate downtime.

Also, said Flanagan, the technologies had facilitated its digital transformation journey, resulting in better service to customers.

Predictive pack

WEHR Group used Action Point’s ‘out of the box’ predictive maintenance pack called IoT-PREDICT. It comprises Dell hardware with Intel and Microsoft elements. Sensor data is gathered through the Dell Edge Gateways, before being passed to the Azure IoT Hub. From here, Azure Time Series Insights and Azure Analytics process the data and feed analytics dashboards and mobile apps.

DAVRA Networks is a vehicle monitoring company, and CEO Paul Glynn demonstrated how everything from a school bus to a heavy excavator can be monitored for multiple parameters, from performance and maintenance perspectives, to geo-fencing and driving styles.

Glynn talked about reports of IoT project failures and said, “The guys who aren’t failing are the ones who are using platforms, the ones who are going about it in a structured way.”

He said the common causes of failure were often poor communication between implementers and users, projects going to too slowly, and issues of quality of output where users did not get what was expected.

Jason Kay, chief commercial officer with food supply chain company IMS Evolve, showed dramatic results for chilled food distribution, or ‘cold chain’.

Kay said that there is a United Nations effort to reduce food waste, where currently in the west it can be as much as 50% through the supply chain. The company set out to use existing data to make the supply chain more efficient, but leveraging IoT to gather data from a wider set of sources and process it more efficiently to improve outcomes.

Integration and insights

The company’s technology can integrate with existing and future infrastructure, focusing on analysis, control and automation, he said.

“IMS Evolve transforms the profile of the operational costs for the world’s leading retailers through better integration of the enterprise model,” said Kay.

The company’s approach is to employ edge-based analytics, leveraging Dell gateways, managing local automation transactions. This breaks reliance on inflexible legacy datasets, said Kay.

The results are tangible, with figures such as a 49% reduction of stock losses, 30% reduction of customer complaints, 40% reduction in reactive maintenance calls, 80% reduction in central resource requirements. Impressively, IMS Evolve said there was a $7 million energy saving in the single refrigeration initiative, while there was 99.98% consistent availability of critical assets through improved maintenance.

Kay said that the technologies allowed better choices to be made in making sense of data already available, driving increased customer value, and developing long term partnerships to support core purposes for businesses.

Bovine Fitbit

In a somewhat unusual application, Dr Alan Davy, Research Unit Manager ENL, TSSG, described how the equivalent of a fitness tracker for cows had allowed dairy farmers to reduce the impact of lameness in cattle, which directly affects milk production.

Dr Davy said a motion tracker fitted to dairy cows could monitor their movements, recording when the cows lay down and for how long, even measuring how quickly they were able to stand up. Analysis would then allow farmers to identify which ones were in the early stages of lameness.

Lameness often involves infection which requires antibiotics. However, a cow treated with antibiotics could be out of milk production for up to six weeks. Early detection allows other treatments that do not always require antibiotics, meaning cows can often be reintroduced to full production or not leave it at all.

Cow 2 Cloud is an SFI funded project that has been dubbed “Fitbit for cows”. Dr Davy said that in this instance the sensors to be fitted to the cows were difficult to source, with few suppliers, but that “the infrastructure elements are pretty much stable”.

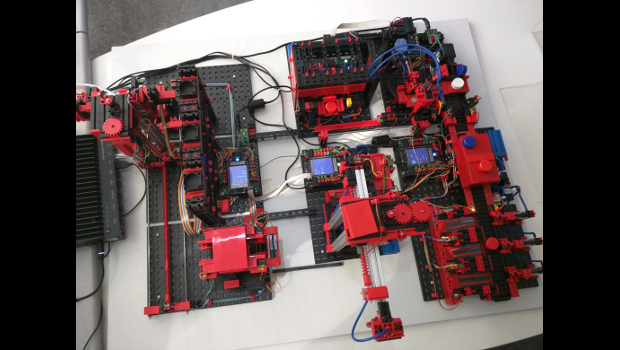

In the IoT lab, numerous other demonstrations were on show. From weather sensing and visualisation to watching cement dry—literally. A company called WMC sensored and monitored the drying process for the special concrete used in the bases of wind turbines for a wind farm in the west of the country. The company’s systems allowed the base to be verified as safe to support the specific type of loading experienced through the lifecycle of a wind turbine.

Robust solutions

Dell EMC can provide the entire infrastructure necessary for IoT now, and, with partners, can guide anyone who has a requirement to a robust solution, said Jeff McCann, global lead, IoT and OEM, Customer Solution Centres, Dell EMC. McCann said that the conversations the company is having with customers and interested parties is varies from those who are looking at the broad possibilities, down to those who have a need “that they just can’t crack”.

Despite the diversity of applications, he said, there was a consistency in where organisations tended to need help, and the IoT Lab allows Dell EMC the ability to model and bring to proof of concept solutions for all kinds of customers.

TechCentral Reporters

Subscribers 0

Fans 0

Followers 0

Followers